Trumpf Fibre 3030 3 KW Laser

Trumpf Fibre Laser for high precision quality cut components. (Mild Steel - 20 mm) (Stainless Steel - 15mm) (Aluminium - 15mm) (Brass - 6.0mm) (Copper - 6.0mm)

Below is a list of the machinery we use in our manufacturing process:

Trumpf Fibre Laser for high precision quality cut components. (Mild Steel - 20 mm) (Stainless Steel - 15mm) (Aluminium - 15mm) (Brass - 6.0mm) (Copper - 6.0mm)

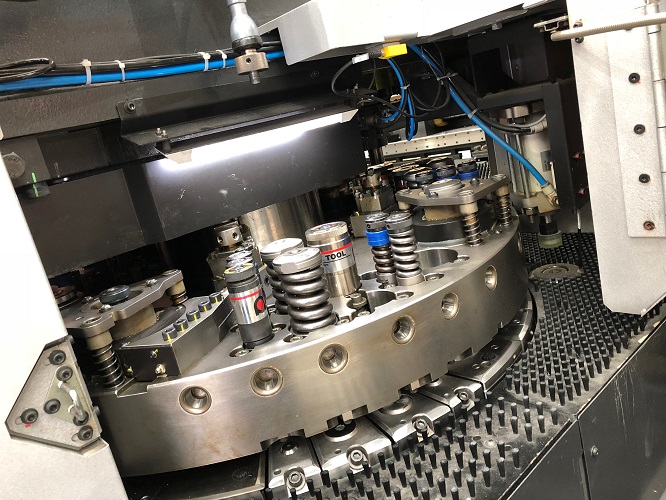

High speed Punching machine. 51 Station Turret with 4 autoindex. Maximum sheet size: 1250 x 4000

Bystronic Expert 150 Ton CNC 8 Axis Press Brake. Folding capacity of 4100mm.

Bystronic Expert 100 Ton CNC 8 Axis Press Brake. Folding capacity of 3100mm.

Amada 1250mm folding machine. Quick set up for large and small production runs.

Large selection of Thick Turret tooling. From single round holes to complex forming tools.

an automatic tool grinder design specifically for high quality grinding of sheet metal tooling.

We have a large selection of forming tools, which accommodates most requirements. Using our suppliers we can design and produce tooling to suit manufacture.

Quickly and accurately add inserts and fasteners to sheet metal parts.

The 32 RB series deburring, edge rounding, laser oxide removal and finish machine